OM 22

Industrial benchtop micro-ohmmeter – High accuracy: 0.03 %

Industrial benchtop micro-ohmmeter – High accuracy: 0.03 %

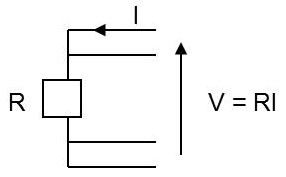

OM 22 Industrial benchtop micro-ohmmeter is used for 4-wire measurement of very low resistance values up to 20 KΩ with an accuracy of 0.03% RDG and a 0.1 µΩ resolution. Programmable, it is particularly suited for use on test benches with repetitive measurement tasks. The reliability and accuracy of the measurements is improved by a low temperature coefficient of 10 ppm/°C, automatic removal of EMF parasites before each measurement, metal temperature compensation and compensation of ambient temperature.