EPM

Electrolytic starter (LRS) for slip ring motors from 500 to 20,000 kW

Electrolytic starter (LRS) for slip ring motors from 500 to 20,000 kW

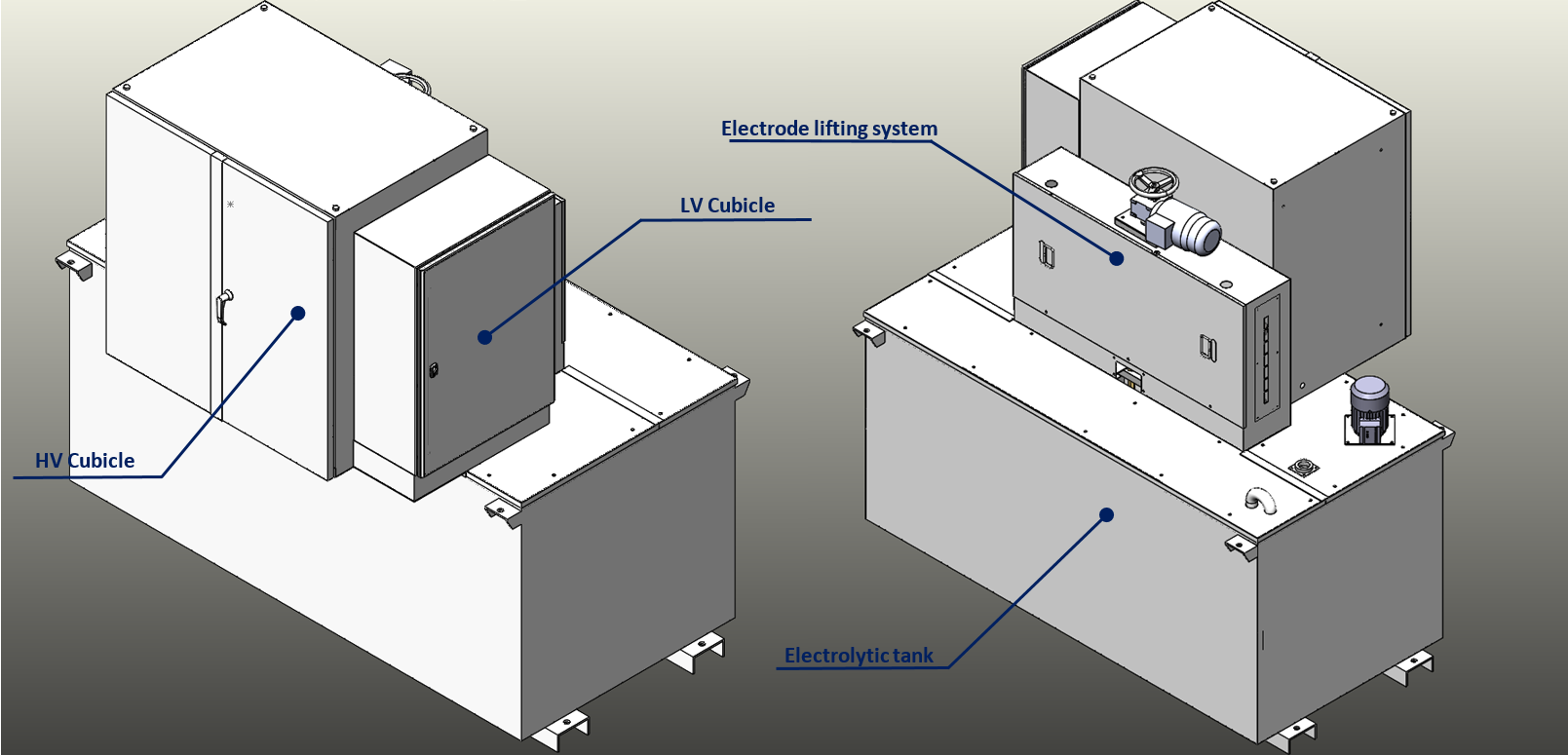

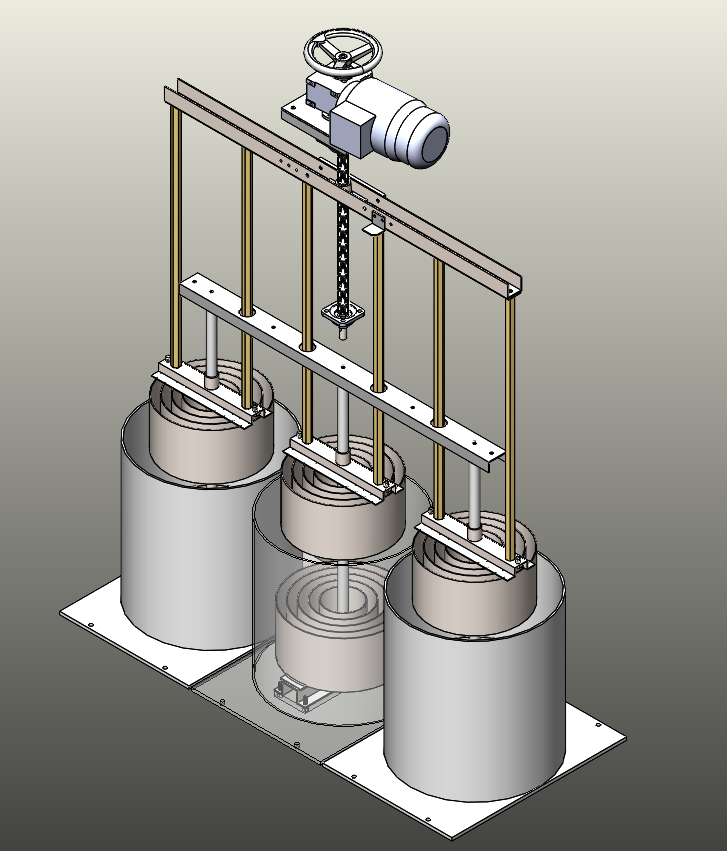

The EPM electrolytic starter is AOIP’s solution to start slip ring motors with heavy duty cycle and high power. Made in France and using premium materials, the EPM has proven to be reliable and sturdy, even in the most challenging environment.

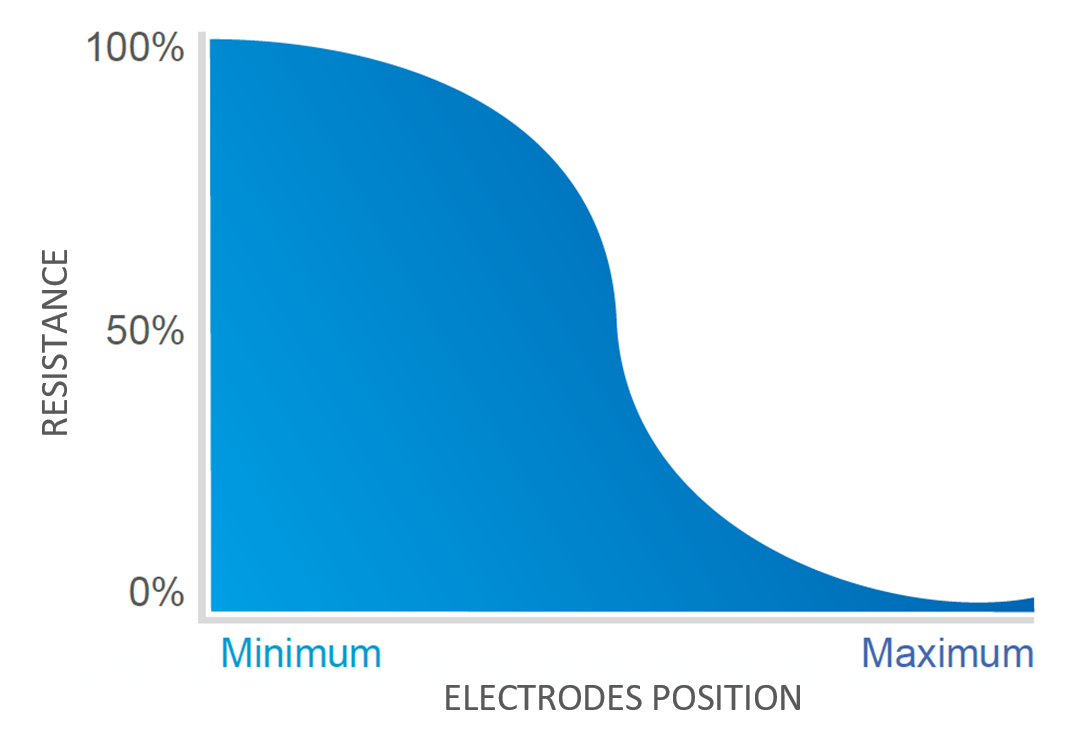

- Smooth progressive acceleration

- Wide range of applications

- Sturdy and reliable

- Customised for each application

- Reduced maintenance